Understanding Rapid Tooling Services

Rapid tooling services are revolutionizing the way industries approach product development and manufacturing. When you think about the typical process of creating molds or tools, it can sound about as exciting as watching paint dry. But with rapid tooling, you’re looking at a dynamic, swift solution that accelerates the entire production timeline. This service utilizes advanced technologies like 3D printing and CNC machining, allowing manufacturers to create prototypes and production tools in a fraction of the time it traditionally takes. Whether you’re in automotive, aerospace, or consumer goods, rapid tooling can dramatically reduce your time to market.

Real-World Applications of Rapid Tooling Services

Consider a team working on a new product launch. They’ve got the concept down, but when it comes to prototyping, they face delays from conventional tooling methods. By integrating a rapid tooling service, they can have functional prototypes made in just days instead of months. This not only boosts team morale but allows for faster iterations and refinements based on initial testing and consumer feedback. Companies that adopt this approach often find themselves with a competitive edge, as they can pivot quickly based on market needs and stakeholder input. It’s all about staying agile in an increasingly fast-paced business environment.

The Advantages of Rapid Tooling Making Services

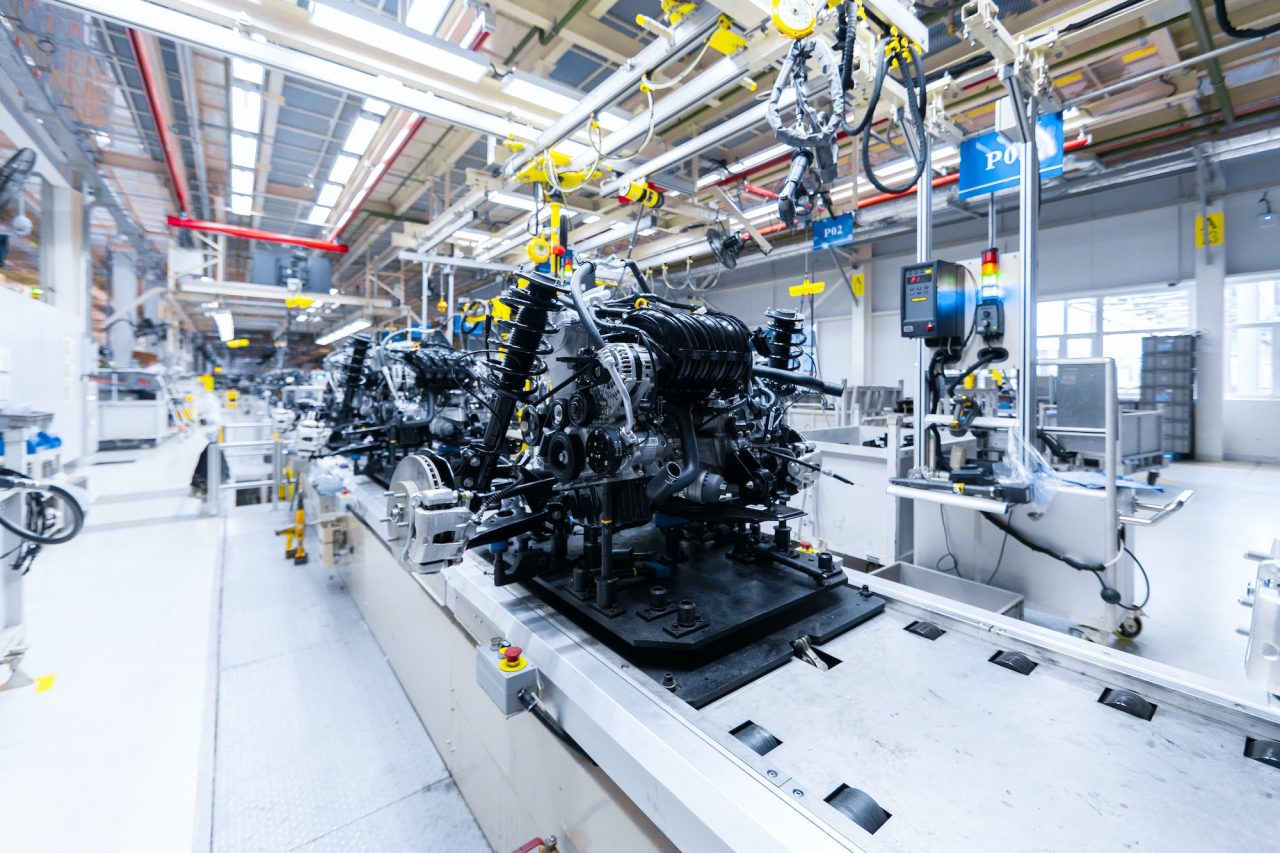

Now, let’s dive deeper into what sets rapid tooling making services apart. These services are not merely about speed; they also encompass precision and flexibility. With the ability to use different materials and techniques, manufacturers can devise tailored solutions for specific challenges. For example, automotive companies often utilize rapid tooling to create custom parts that fit uniquely within their vehicles, ensuring optimal performance and aesthetic value. The key takeaway is that this service doesn’t just save time; it dramatically enhances the adaptability and quality of the production process. You get high-quality tools that meet exact specifications without the typical long wait times.

Your Go-To Choice: APT-Mold

When it comes to sourcing reliable rapid tooling making services, look no further than APT-Mold. They are a frontrunner in the industry, combining cutting-edge technology with years of expertise. Their team understands the nuances of toolmaking and is dedicated to providing solutions that are not only fast but also cost-effective. Plus, their commitment to quality ensures that all products meet the highest industry standards. With a robust supply chain and an impressive track record, APT-Mold stands out as a trusted partner in your manufacturing journey.

Integrating Rapid Tooling Making Services into Your Business Strategy

If you’re contemplating how to incorporate rapid tooling making service into your workflow, take a moment to reflect on your current production inefficiencies. By leveraging these services, you can not only reduce lead times but also enhance product quality. Many companies have restructured their R&D timelines around rapid tooling, allowing them to experiment with designs more freely and iterate faster than ever before. Imagine being able to test multiple versions of a product side by side—no more waiting weeks for each prototype only to discover it’s not quite right. Embracing rapid tooling means your business keeps pace with, and often leads, market trends. Moreover, the insights gained through this process feed directly back into your design and engineering strategies, providing tangible data to inform future innovations.

Enhanced Efficiency with Rapid Tooling Making Services

As industries evolve, the importance of rapid tooling making services becomes undeniable. The integration of these services not only turbo-charges production cycles but also allows for real-time feedback and adjustments. Think about the last time you encountered a major setback due to a design flaw discovered late in the game. With rapid tooling, those headaches can be significantly minimized. You can test, analyze, and modify your designs almost instantaneously. This empowers teams to make informed decisions based on actual data rather than projected outcomes, ultimately leading to better end-products. In a world where time equals money, utilizing rapid tooling services can streamline workflow, enhance collaboration, and foster innovation.

Final Thoughts: Why APT-Mold Should Be Your Partner

In conclusion, if your business is looking to modernize its manufacturing processes, embracing rapid tooling services is a must. These services not only reduce lead times but also increase the precision and quality of your products. Choosing APT-Mold as your go-to manufacturer ensures you have a partner who understands the landscape of rapid tooling and can provide tailored solutions that will keep your business at the forefront of your industry. Their expertise and commitment to excellence will guide you through every stage of the process, ensuring that your project is executed with skill and care. Consider APT-Mold not just as a supplier, but as a strategic ally in achieving your manufacturing goals.