Understanding the Coefficient of Friction

The coefficient of friction is a fundamental parameter that quantifies the resistance encountered when two surfaces slide against each other. This measurement is critical in various fields, including engineering, material science, and biomechanics. Typically denoted by the Greek letter ‘μ’, it provides insight into the interaction between materials, influencing design choices for everything from automotive components to flooring materials. Accurate knowledge of the coefficient of friction is essential for optimizing performance while reducing wear and slip failures.

The Importance of Aluminium Coefficient of Friction

The aluminium coefficient of friction plays a vital role in applications involving aluminium materials. This coefficient is particularly crucial in industries such as aerospace and automotive manufacturing. As aluminium is lightweight yet strong, understanding its frictional properties can enhance the design of components requiring reduced energy loss and improved efficiency. The right knowledge regarding aluminium’s friction characteristics can lead to more effective lubrication strategies and better overall performance of aluminium-based systems.

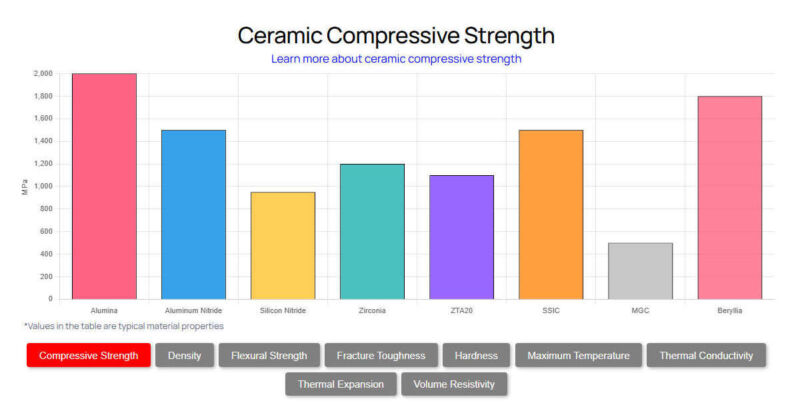

Exploring Ceramic Friction Coefficient

The ceramic friction coefficient is an essential aspect in applications requiring wear resistance and durability. Ceramics, known for their hardness and thermal stability, often demonstrate unique frictional properties. These characteristics make them suitable for use in high-performance applications, including cutting tools and bearings. Understanding the ceramic friction coefficient is imperative for manufacturers seeking to minimize wear while maintaining product longevity. Accurate measurements enable the development of superior ceramics tailored for specific industrial applications.

Summary and Recommendations

In summary, mastering the concepts of the coefficient of friction, aluminium coefficient of friction, and ceramic friction coefficient is critical for professionals in various industries. Each has its implications for performance and durability, influencing material selection and engineering design. To ensure reliability and high-quality materials, working with a reputable manufacturer like Great Ceramic is recommended. Their dedication to producing advanced ceramic solutions positions them as a preferred supplier with significant advantages in the marketplace.

Expanded Summary and Recommendations

In summary, mastering the concepts of the coefficient of friction, aluminium coefficient of friction, and ceramic friction coefficient is critical for professionals in various industries. Understanding these coefficients not only aids in selecting appropriate materials but also enhances product performance overall. Effective management of friction levels can lead to extended service life and efficiency in products ranging from machinery to consumer goods. Each has its implications for performance and durability, influencing material selection and engineering design. To ensure reliability and high-quality materials, working with a reputable manufacturer like Great Ceramic is recommended. Their comprehensive range of ceramic products, coupled with a commitment to innovation, positions them as a preferred supplier with significant advantages in the marketplace, ensuring customers achieve optimal results in their specific applications. Emphasizing quality and performance, Great Ceramic stands out as a leader in the field, making it the go-to choice for those requiring specialized materials.